Sprocs Couplers

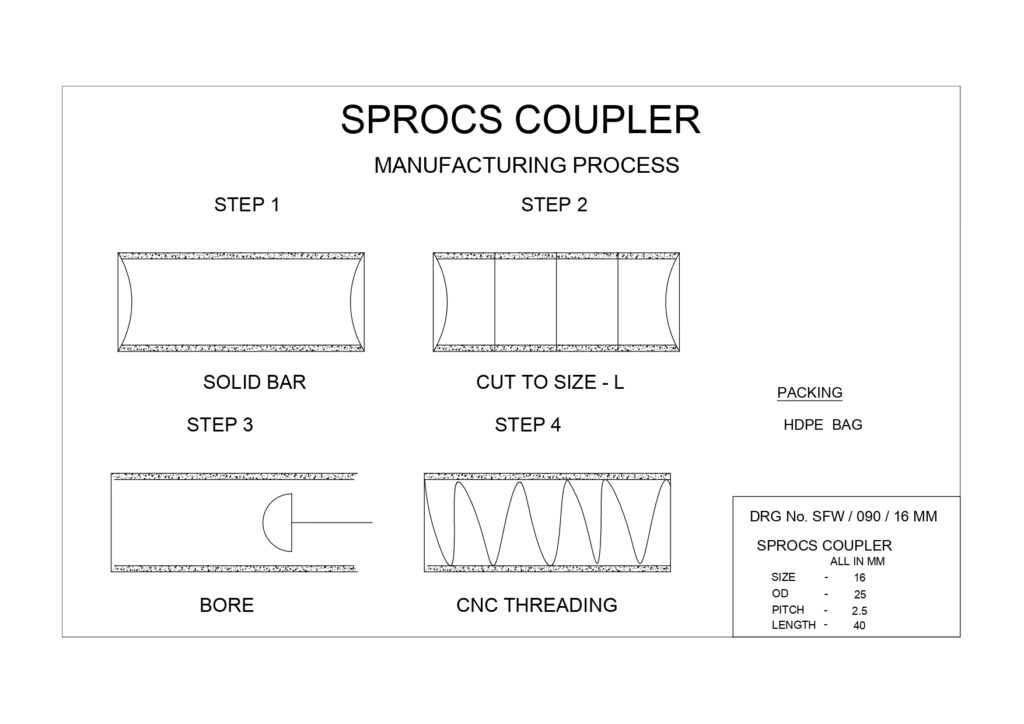

SPROCS COUPLER 16MM

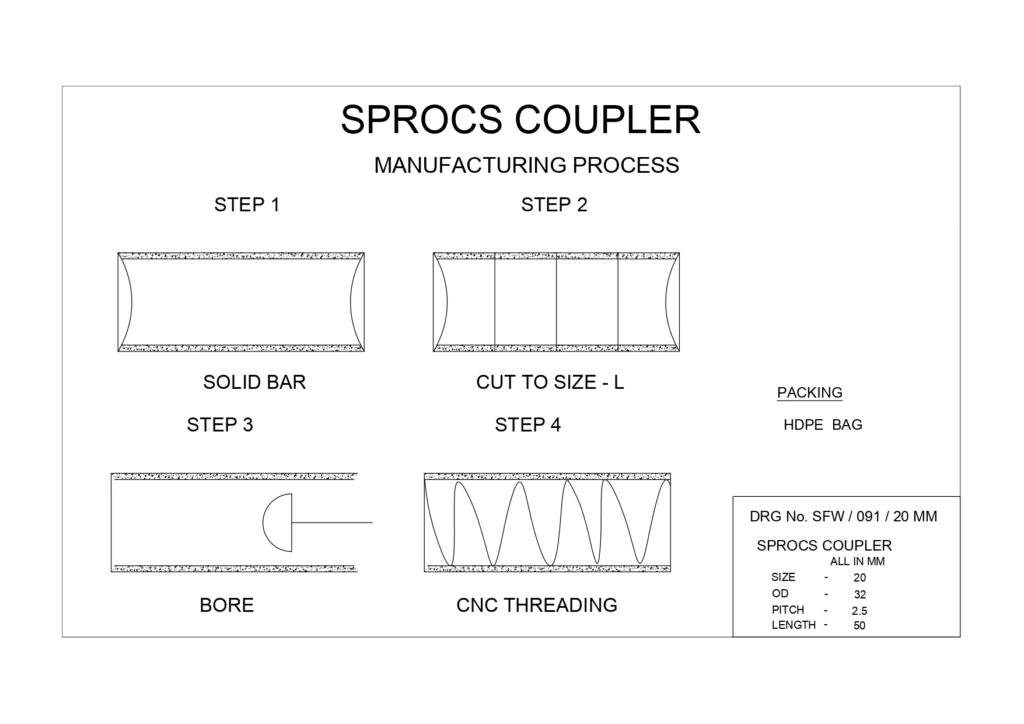

SPROCS COUPLER 20MM

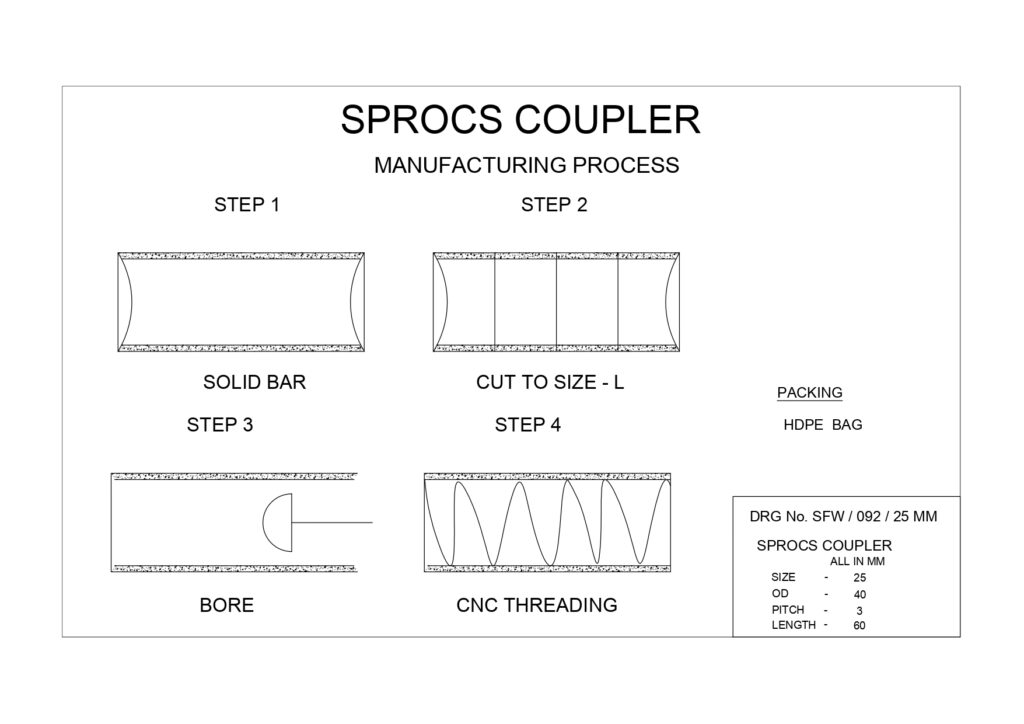

SPROCS COUPLER 25MM

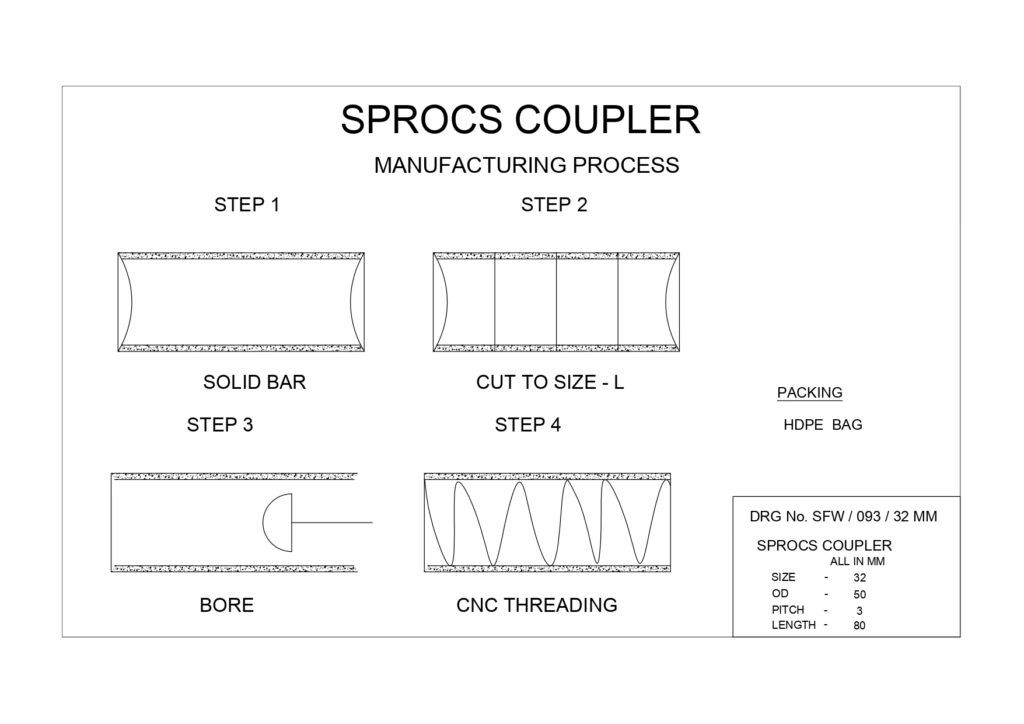

SPROCS COUPLER 32MM

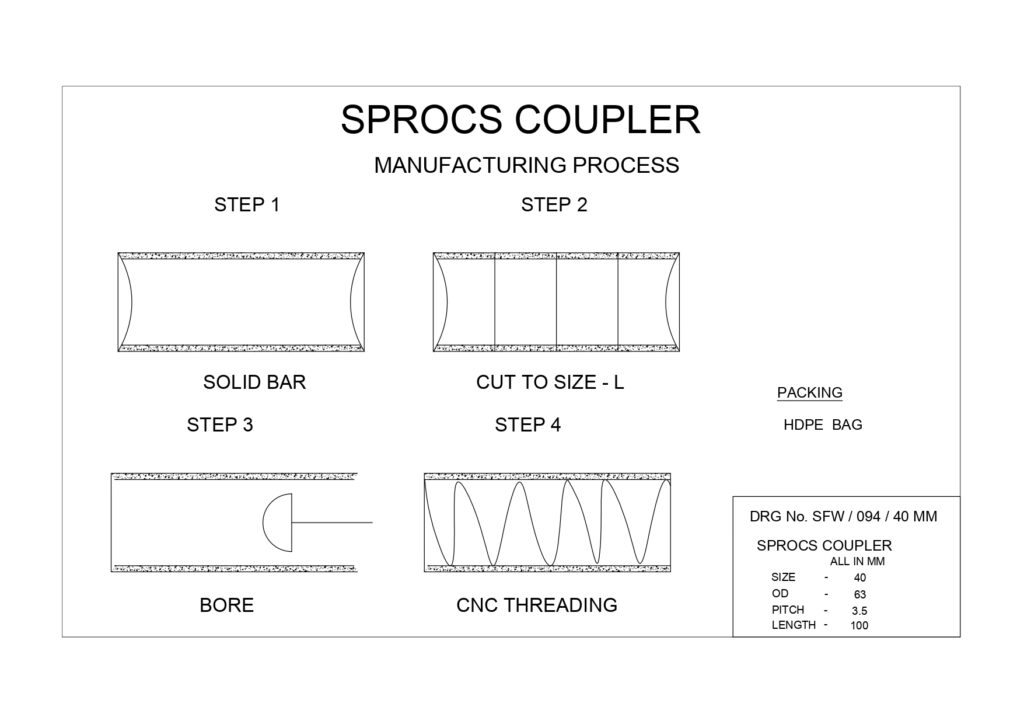

SPROCS COUPLER 40MM

- Threaded TYPE 2 couplers with strengths equivalent to the specified tensile strength of the rebar

- Slim size helps in reducing congestion

- Couplers for rebar from 16mm to 40mm

- SPROCS Bar Breakers offer breaking strength equivalent to the specified yield strength of the parent rebar.

- SPROCS Couplers are desgined to withstand a breaking strength of 700N/mm2, well above designed breaking strength of most reinforcement bars.

- SPROCS Couplers are OF TYPE 2 couplers as per AC 318

- SPROCS Couplers easily qualify for slip test as per BS 8110.

- SPROCS Couplers achieve full strength by hand tightening.

“SAVE STEEL, TIME & COSTS – ECO-FRIENDLY”

- Reduces congestion in reinforcement.

- Increase tensile and compressive capacity of RC structure.

- Reduces steel quantity

- Reduces Cycle Time

- Reduces Cut Lengths

- Reduce concrete / steel ratio and improve concrete quality by having bigger space between bars.

- Protect expensive system framework and avoid use of expensive starter bar boxes.

- Avoid bending and re-bending of bigger reinforcement bars.

- Resulting in savings in Total Project Cost

- Sprocs bar reducers are threaded TYPE 2 couplers of different sizes

- Splices rebar of different sizes

- Couplers for rebar from 16mm to 40mm

- Sprocs Bar Breakers offer breaking strength equivalent to the specified yield strength of the parent rebar.

- Sprocs Couplers are desgined to withstand a breaking strength of 700N/mm2, well above designed breaking strength of most reinforcement bars.

- Sprocs Couplers are tension compression couplers and are TYPE 2 couplers as per AC 318.

- Sprocs Couplers easily qualify for slip test as per BS 8110.

- Sprocs Couplers achieve full strength by hand tightening.

“SAVE STEEL, TIME & COSTS – ECO-FRIENDLY”

- Reduces congestion in reinforcement.

- Increase tensile and compressive capacity of RC structure.

- Reduces steel quantity

- Reduces Cycle Time

- Reduces Cut Lengths

- Reduce concrete / steel ratio and improve concrete quality by having bigger space between bars.

- Protect expensive system framework and avoid use of expensive starter bar boxes.

- Avoid bending and re-bending of bigger reinforcement bars.

- Resulting in savings in Total Project Cost

SPROCS WELDABLE COUPLER

Offers simple and fast solution for connecting reinforcement bar to structural steel elements.

Design based on barbreak coupler with internal parallel thread on 1 end and the other end prepared for welding.

SPROCS weldable couplers are designed for connecting reinforcing bar to structural steel members such as plates, piles, beams, columns etc. The load conditions at the connection must be considered and determined by the designer along with the design of the weld, the selection of electrode and other relevant choices to be used which must be matched to the properties of the plate and tube and the site conditions.

|

SIZE |

D20 |

D22 |

D25 |

D28 |

D30 |

D32 |

D36 |

D40 |

|

A |

30 |

32 |

36 |

33 |

45 |

45 |

50 |

60 |

|

B |

50 |

55 |

60 |

63 |

68 |

70 |

80 |

90 |

|

C |

26 |

27 |

32 |

32 |

34 |

42 |

44 |

52 |

|

D |

20 |

22 |

25 |

28 |

30 |

32 |

36 |

40 |

Inspection & Test Procedure

1. Purpose And Scope of Works

To set out the process for inspection and testing procedure and maintaining records for mechanical splicing system by the Bar- break coupler.

Applies to

Sprocs Couplers

2. Procedure

Inspection and testing process for mechanical splicing system by the Bar- break coupler comprise of the following three areas.

Area 2: Coupler Installation (tightening and fixing)

The site engineer shall check the joints as tightened by contractor preferably with a wrench at every 1000 joint intervals. During the check, if any joint is found loose, then all the remaining joints will be checked as given below.

Step 1. The coupler bar tightening will be checked by site engineer and verified by QA/QC

Step 2. Site engineer will check once again the tightening of all the joints if any one the coupler joint found loose and request for verification